inotec Barcode Security

inotec Barcode Security is a market-leading provider of barcode and RFID data carriers as well as a competent partner in the planning of logistics concepts and the implementation of individual barcode solutions.

Headquarters

Neumünster, Germany

Additional locations

France, England, Netherlands, Czech Republic

Industry

Automatic identification

Products

Sequential barcode and 2D-code labels, RFID smart labels, blank labels, metal plates, ceramic labels

Applications

Labelling blood transfusion bags; reusable supermarket trays for fruit, vegetables, meat; library cards; luggage tags at airports; RFID applications for passports, time recording in high-performance sports; authenticity verification for medicines; access control; location control in industrial and hospital logistics; warehousing; product imprints; ceramic barcodes for the steel industry that are heat-resistant up to more than 1600 degrees Celsius; security labels protecting against product manipulation and piracy

Expertise

Processing and development of high-quality materials for demanding data carrier applications

Since

1989

Internet

www.inotec.de

Portrait

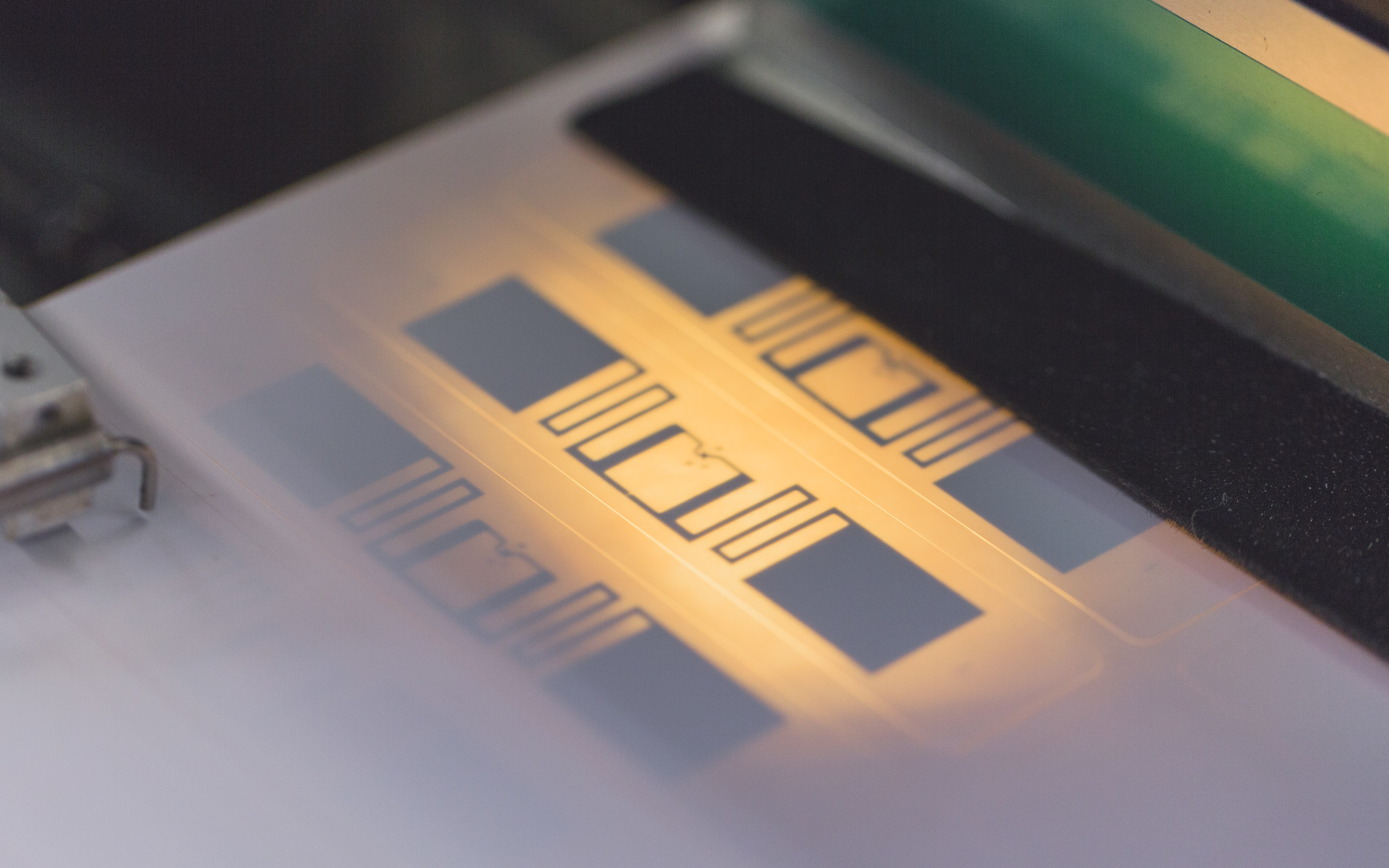

Printing data carriers

The company inotec Barcode Security grew out of a printing business in 1989. From a technological perspective the roots are obvious, because the production of labels is based on conventional printing methods such as phototypesetting, thermal transfer or digital printing.

Long-time managing director Mo Bader was decisive in his influence on the company’s development, which has its headquarters in Neumünster, a small city north of Hamburg. The mechanical engineer has a background in medical technology, a field in which he previously headed several companies. He adopted this sector’s concept of quality and anchored a comprehensive quality management system in inotec Barcode Security that to this day sets standards. An example is a washable label with a serial number for use on blood transfusion bags.

Up until today, these labels, once inotec Barcode Security’s first order, are manufactured according to strict quality standards. The company also markets approximately 150 other products. They are made from more than 20 different printing materials and a variety of partly self-developed adhesives. In the meantime, the product portfolio has been extended by a range of modern RFID chip applications.

Application

RFID labels for the supermarket chain Migros

In 2015, the Swiss supermarket chain Migros introduced approximately 400 meat containers with RFID tags from inotec Barcode Security into circulation. These containers are used for the daily supply of fresh meat to more than 100 supermarkets. The RFID-based data pool allows gapless tracking of the transport boxes from the production of the meat to when the product lands on supermarket shelves. For example, supermarket branches are automatically notified of the product delivery time once it has been loaded in the meat factory. This avoids lost or incorrect deliveries and the path the goods take to the customer is trackable from start to finish.

inotec Barcode Security's challenge was to develop exceptionally robust labels. The containers are regularly cleaned at very high temperatures. During transport and storage, they are exposed to the elements and must endure the effects from bumping and scratching. Importantly, inotec Barcode Security had to make certain that bacteria cannot accumulate under the labels and that the materials used are in line with food regulations.

Using the in-mould process, during which labels are injected directly into the plastic of the container, inotec Barcode Security was able to provide a solution to meet these challenges.

Markets

Positioned Europe-wide

In addition to its headquarters in Neumünster, inotec Barcode Security has offices in France, England, the Czech Republic and the Netherlands. The chosen European footprint is intended to ensure the company's further growth. Overall, the company markets its products in more than 20 countries.

Insights

Every company and each employee are unique and have a distinct history. The following texts offer an impression of the motivation, perspective and convictions of the people behind the stories.